WHAT IS ROLLING MARGIN AND HOW TO FIND ROLLING MARGIN ? WITH FREE EXCEL SHEET. EASY AND SIMPLE EXPLANATION OF ROLLING MARGIN OF STEEL.

Rolling margin

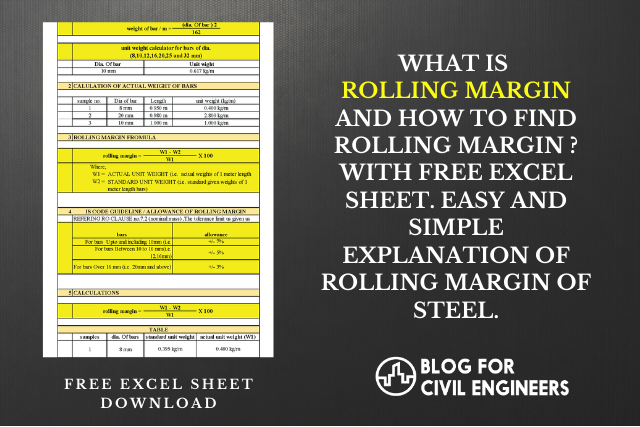

Rolling margin in terms of construction the industry is basically the difference of actual weight of steel to the standard weight of steel (Rebars).

To keep the record of the rolling margin of lots or mass quantity of steels arrived at the site is important because ultimately it affects the cost of the project. As we all know that the steel prices are very high, and to maintain the economy of the project one should be able to find the rolling margin of the different diameters of the steel.

IS CODE definition.

“Rolling margin is the deviation of actual unit weight of the steel to the standard unit weight of steel as per IS 1786”

HOW TO FIND ROLLING MARGIN?

NOTE:

For the ease of understanding the concept, I have made an excel sheet with simple and easy calculation so that it’s easy for you all to understand the concept properly.

You can directly download the excel sheet if you want to skip the explanation….. it’s totally up to you.

So below are some important points which you can refer to if you don’t understand the excel sheet which I have attached below.

1. Rolling margin of steel is calculated by taking samples of different diameter of bars and comparing them with the theoretical or standard weight of the bar.

2. When steel has arrived at the site, the sample of length (W1) is taken, the length of the sample is kept as 1m (meter). So that we can compare it with the standard unit weight of the different bars.

3. However there will be differences in length due to human errors but try to keep it as accurate as possible for better results.

4. After taking the actual weight of the different diameter of bars you just have to compare it with the IS CODES GUIDELINES for nominal mass. Which is given below

|

bars |

allowance |

|

For bars Up to and including 10mm (i.e. 8,10mm) |

+/- 7% |

|

For bars Between 10 to 16 mm (i.e. 12,16mm) |

+/- 5% |

|

For bars Over 16 mm (i.e. 20mm and above) |

+/- 3% |

5. To find the rolling margin, the formula is given below

Where you have to take the difference of actual weight and standard weight and divide it with the actual weight and multiply the whole calculation with 100 to get the answer in %For better understanding formula is given below,

\[Rolling~Margin = {{W_{1} –W_{2} } \over {W_{1}} X ~ 100}\]

Where,

W1 = ACTUAL UNIT WEIGHT (i.e. Actual weights of 1 meter length samples)

W2 = STANDARD UNIT WEIGHT (i.e. standard given weights of 1-meter length bars)

EXCEL SHEET EXPLANATION

The first point in the excel sheet explains the standard unit weight of the bars which is given by the formula,

Unit weight of bar = d2 / 162

You just have to change the diameter in the excel sheet and you will get your unit weight of the steel

Now coming to the second point where you have to enter your observations. Again in that table, you have to enter the diameter of bars, length, and weight of the samples which you have taken for testing purpose.

|

2 |

CALCULATION OF ACTUAL WEIGHT OF BARS |

|||

|

|

||||

|

|

Sample no.

|

Dia of bar

|

Length

|

unit weight (kg/m)

|

|

|

1 |

|

|

|

|

|

2 |

|

|

|

|

|

3 |

|

|

|

The third point explains the formula for finding the deviation of steel weight. As it’s a self-explanatory section.

The fourth point will give you the guidelines set by IS CODE for the allowance of steel deviations which we will use in our final table.

I have included this clause in the excel sheet just for ease of understanding.

The fifth point is the main part of the excel sheet which will be helpful in calculating the result.

|

TABLE |

||||||

|

|

samples |

dia. Of bars |

standard unit weight (W2) |

actual unit weight (W1) |

||

|

|

1 |

8 mm |

0.395 kg/m |

0.400 kg/m |

||

|

|

2 |

10 mm |

0.617 kg/m |

1.000 kg/m |

||

|

|

3 |

20 mm |

2.470 kg/m |

2.800 kg/m |

||

|

|

||||||

|

|

Rolling Margin |

IS CODE (range) |

result |

|||

|

|

1.250 % |

0.423 kg/m |

0.367 kg/m |

ACCEPTABLE |

||

|

|

38.300 % |

0.660 kg/m |

0.574 kg/m |

NOT ACCEPTABLE |

||

|

|

11.786 % |

2.544 kg/m |

2.396 kg/m |

NOT ACCEPTABLE |

||

|

|

|

|

|

|

|

|

1. Diameter of bar = in this section you just have to enter the diameter of the sample

2. Standard unit weight (W2) = as explained earlier you have to take the sample weight for the purpose of comparison with actual unit weight.

3. Actual unit weight = this section will automatically get filled as you have already entered the diameter of the bar.

4. Rolling margin = this section will give you the actual deviation of in percentage with the standard unit weight of the bar.

This concept is also explained earlier in this excel sheet.

6. IS CODE (range) = this section is nothing but the conditions which we have discussed in the fourth section of the excel sheet. And this table will also get filled automatically….and with the help of this, the remark section will give acceptance or not acceptance of the rolling margin deviation.

NOTE = with the help of these excel sheets you can easily calculate a huge amount of calculations. Like in the sheet the example is taken just for 1 m sample.

So for the purpose of industrial use or to calculate the rolling margin of a large amount of steel…..you have to simply take the sample weight and assign that weight to all the lot or quantity of steel of that particular sample and vice versa.

Please let me know in the comment section below or email your problems or any correction in the excel sheet you found.

And yes!!!!

If you like the article then please share it and use it for the convenience and to simplify your work flow.

DOWNLOAD LINK

DOWNLOAD THE EXCEL FILE

THANK YOU SO MUCH , IF YOU LIKE THE CONTENT.

SUBSCRIBE FOR MORE SUCH INFORMATION REGARDING CIVIL ENGINEERING!!!!!

Comments